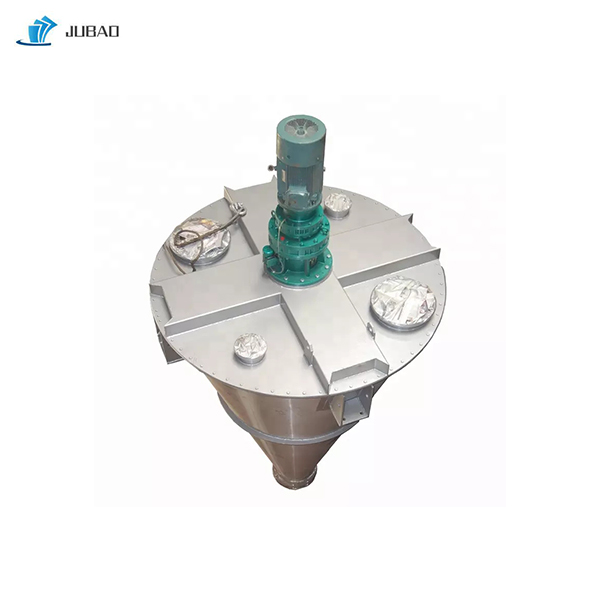

Double helix conical mixer

Volume: 300~20000 L

Mixing Capacity: 100~5000 L

Spindle Speed: 2 – 78 r.p.m

Power: 1.5~55kw

Construction Materials:SUS 316L, SUS304, Carbon Steel

Price: 1800~12000USD

- Description

- Inquiry

Description

What is double helix conical mixer?

Double helix conical mixer machine is a new highly efficient and high-precision mixing equipment. The machine has the characteristics of reasonable structure, convenient operation and maintenance, low energy consumption, large load factor, small volume, airtight operation, etc. The machine can be made of different materials according to the customer’s requirements. There are several kinds of materials to choose from, such as carbon steel, stainless steel, super-heavy explosion-proof type models, and other several models.

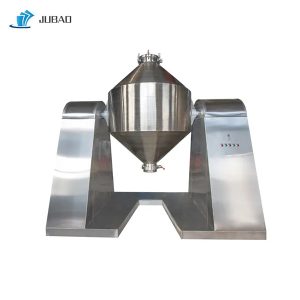

Working principle of double helix conical mixer

The helix rotates and pushes the material to create a composite motion inside the cone. The main motion types are:

1. Make orbital rotation along the wall to push the material in do circular motion;

2. The spin rotation pushes the material up from the bottom edge of the cone;

3. Orbit and spin rotation will absorb part of the material to the bottom of the cone and the material will be pushed up under the action of centrifugal force at the same time;

4. The material fell by its own gravity. Those four movements in the mixer create convection, shearing, and diffusion, so as to achieve rapid and uniform mixing purposes.

Advantages of double helix conical mixer:

1. The double helix conical mixer adopts an advanced structure, easy to operate, safe, and reliable in operation, and the screw shaft has no bottom bearing, which can eliminate the failure caused by the powder leakage of the bottom bearing.

2. The double helix conical mixer not only stirs quickly but also has a very uniform mixing quality. The double helix structure is arranged asymmetrically, and the mixing range is large, so the specific gravity difference is more suitable than special mixing.

3. Compared with the drum mixer, the double helix conical mixer has a significant energy-saving effect, and the energy consumption is reduced by about one-tenth.

4. The wear and pressure input of granular materials is very small, and there is no risk of overheating for the mixing of heat-sensitive materials.

5. The material is very stable after mixing, and no stratification and segregation occur.

6. The seal is dust-free, easy to operate, easy to maintain, and has a long service life. According to user requirements, the cone can be made into a pressure vessel for pressurized or vacuum operation. The cone container can also be dried and cooled through the jacket. The double helix conical mixer is an ideal multifunctional mixing equipment.

If you want more information about the product, please contact us