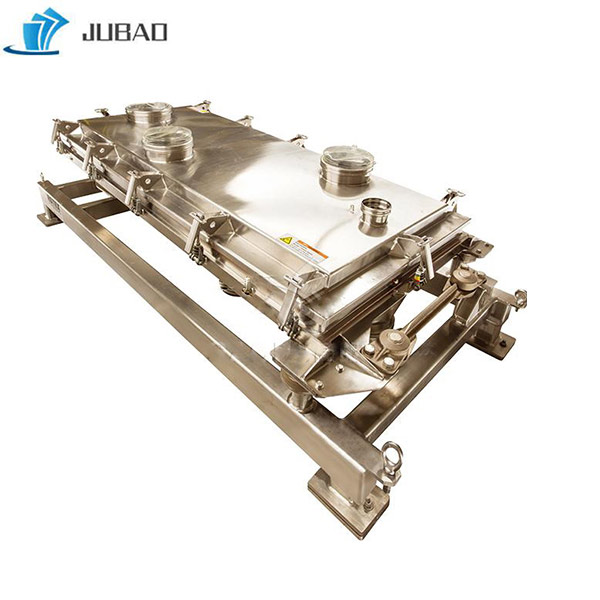

Gyratory vibrating screen

Width(mm): 1200-2000

Length(mm): 3000-4000

Feeding Size(mm): <50 or <75

Screen Deck/Layer No: 1-3

Power(KW): 5.5-11

Structure material option: SUS316L/304, carbon steel

Frequency(r/min): 750-1450

- Description

- Inquiry

Description

What is Gyratory vibrating screen?

The gyratory vibrating screen has a gantry hanger on the outside of the two ends of the frame. It can be used in industries that need to filter powders, particles, and liquids. The shape of inlet and outlet holes and the height of supporting legs can be adjusted to meet the requirements of the production line. This gyratory screening machine is suitable to sieve the uniformed size of materials, it is widely used in the chemical industry, food, sugar making, mining, metallurgy, ceramics, feed, medicine, building materials, paper, and other industries.

Features and Advantages of Gyratory vibrating screen

1. Gyratory vibrating screen for separator screen is a machine with high efficiency and precision.

2. Fully enclosed structure, no dust pollution, improving the working environment of operators.

3. It can effectively eliminate the problem of sieve clogging, increase the capacity of sieve holes, and reduce the damage of sieve holes.

4. Every detail of our gyratory vibrating screen is handled in strict accordance with the standard production. The details reflect the technological level of our factory’s production.

5. Our gyratory vibrating screen has a long service life, which can greatly save costs.

Working principle of Gyratory vibrating screen

The working principle of the gyratory vibrating screen is mainly achieved by using the motion of the eccentric machine, and its motion shape is a constant reciprocating gyro motion. The horizontal circular motion of the material at the feed end gradually changes into an elliptical motion along the length direction and finally becomes an approximate reciprocating linear movement at the discharging end. The material enters the screen body through the feed port, under the action of vibration, can be more evenly distributed in the machine, with small particle sizes of the material quickly through the screen, and large particle sizes of the material on the discharge end movement.

If you want to know more product information, please contact us.